Quality Division

The department stems from the need to guarantee its customers the highest quality on the products that Alphasar manufactures.

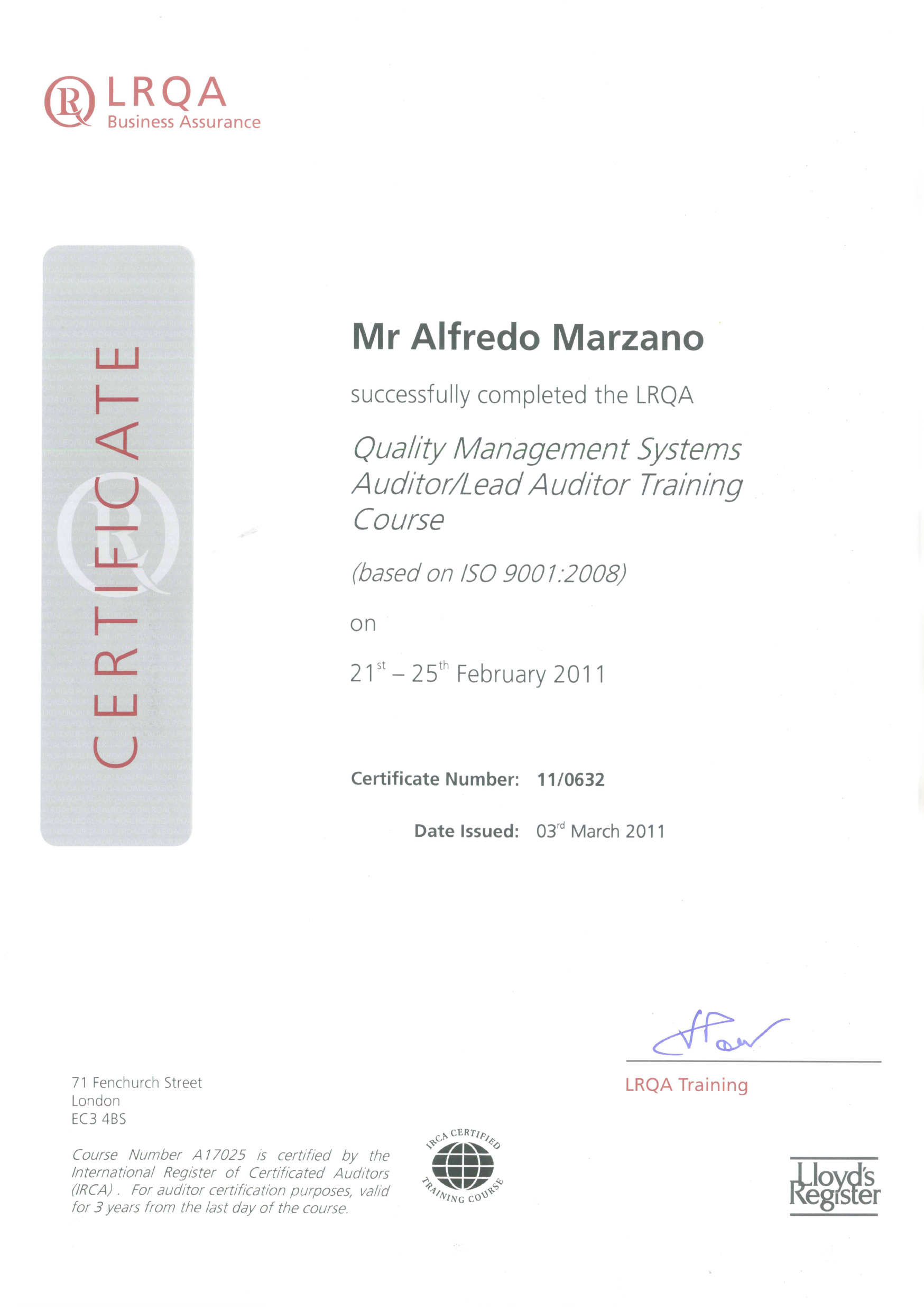

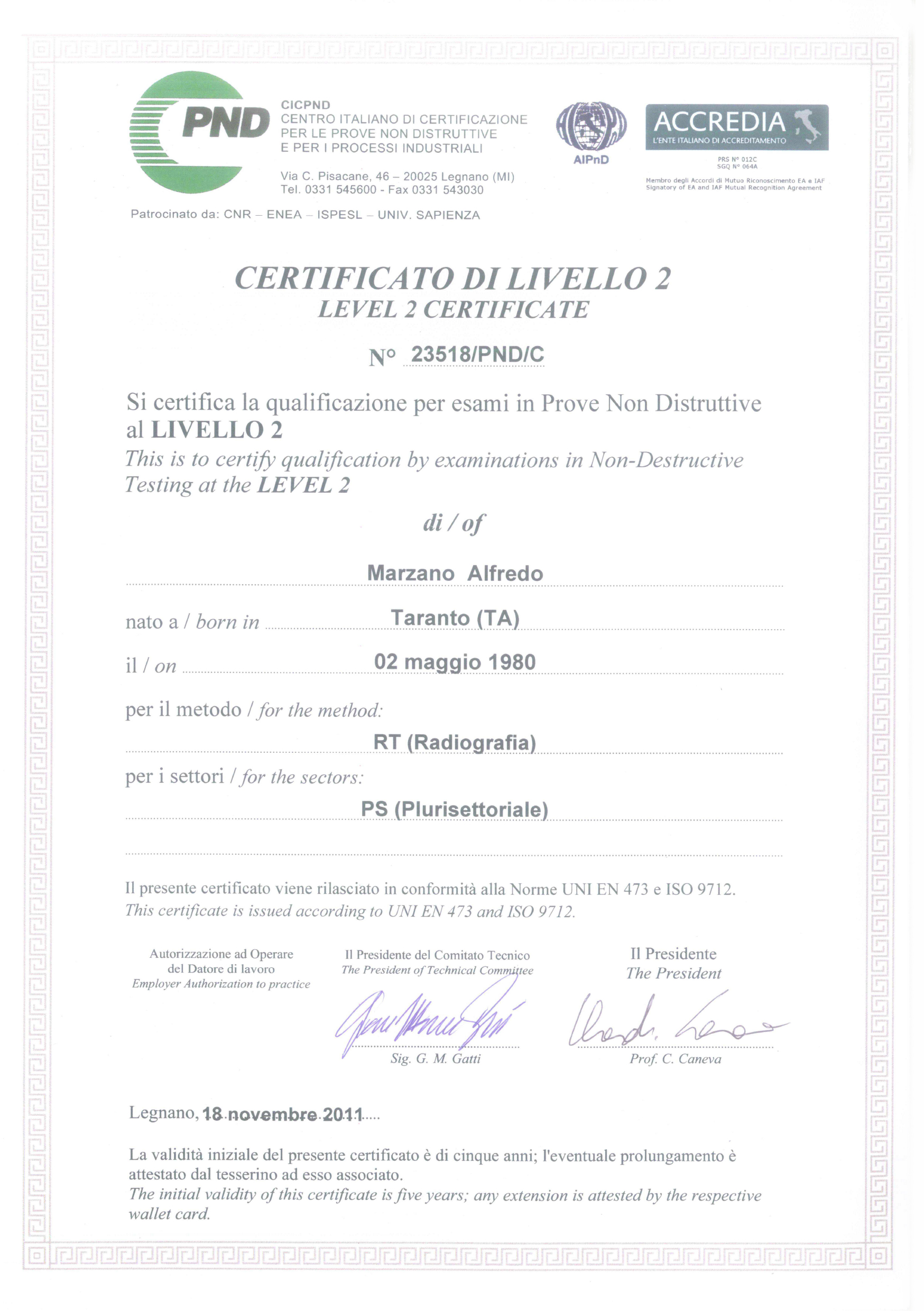

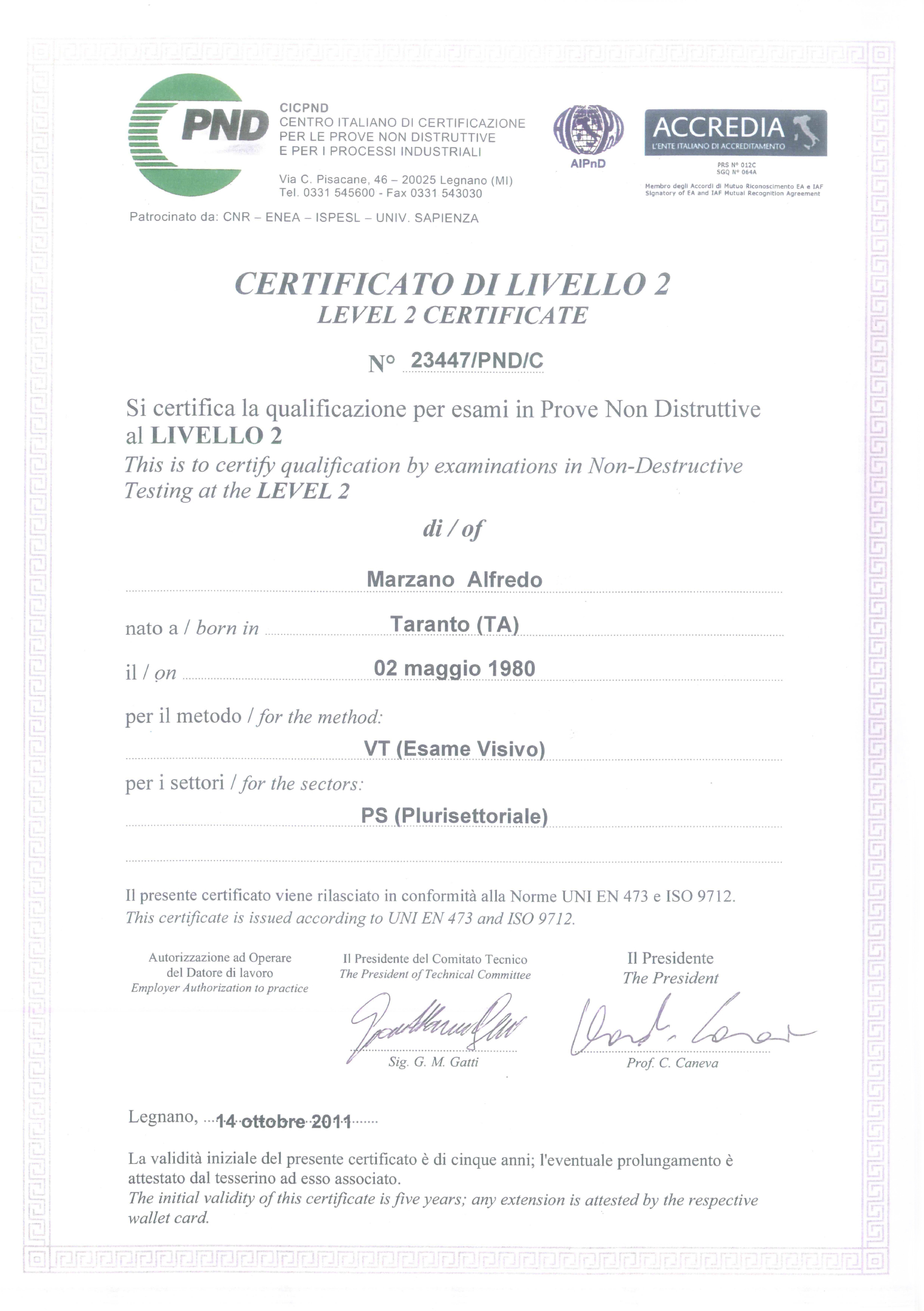

The via Molinara plant is the headquarters of the NDT department, composed of operators qualified in all non-destructive testing according to American and European standards.

The personnel, present in all plants, have multi-sectoral skills in the methods

- radiographic

- liquid penetrant;

- ultrasonic;

- magnetoscopic;

- visual and dimensional

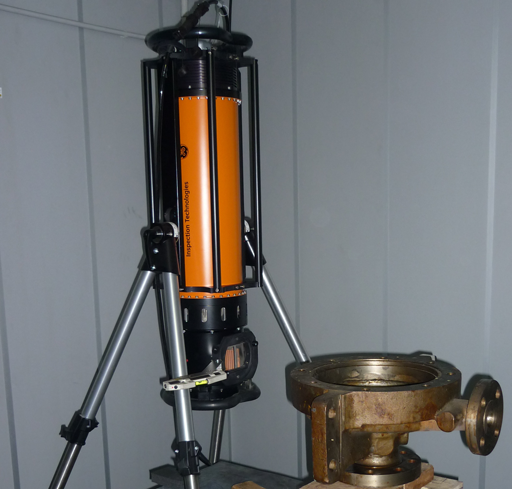

- PMI Niton/Spectrotest material analysis;

- spessimetric;

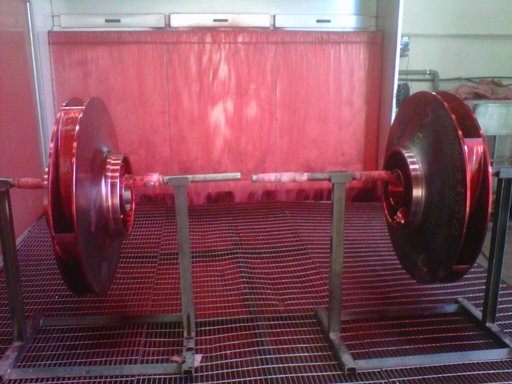

The department has two X-ray bunkers built according to the latest technology, which in addition to guaranteeing a higher quality of inspection also ensure zero impact on the health of its employees.

It is possible to X-ray thicknesses of up to 70 mm.

This result, linked to the power (max. 300 KW at constant potential) and the latest generation of equipment, makes it possible to perform the check not only on welds but also on castings of various geometries and dimensions with a maximum weight of about 10 tonnes. X-ray operators also have specific software for determining exposure times in relation to the material and thickness of the part being examined. Process checks are carried out on materials, in particular the checking of chemical compositions by means of x-ray equipment (Niton PMI) and the analysis and detection of carbon using the ARC and/or SPARK method (Spectrotest).

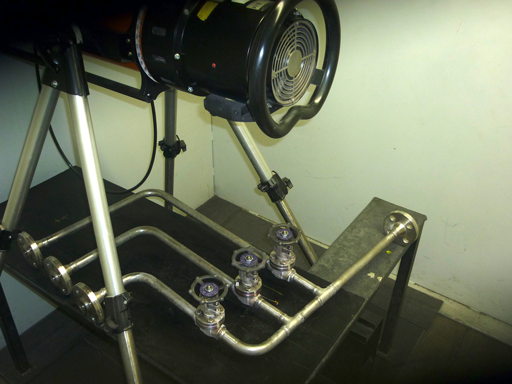

In each plant, there are stations equipped for liquid penetrant testing, magnetoscopic and material analysis for complete monitoring of all company processes.