Welding division

This production unit is one of the most convincing because it is able to guarantee a quality product in a short time frame. Alphasar is able to custom-build lines with Butt Weld, Socked Weld and threaded welds.

All welders are qualified according to ASME IX and EN 15614 standards, for different weld types, materials and thicknesses.

The company has technologically advanced equipment under constant maintenance and calibration monitoring.

Overhead travelling cranes and jib cranes allow the handling of loads of up to 10 tonnes.

This department is divided into clearly defined workstations according to the type of task to be performed, materials and dimensions:

- 4 areas for the construction of welded, threaded pipes and brackets;

- 4 areas for the fabrication of primary and auxiliary connections for the chemical and petrochemical industries;

- 1 area for parts preparation (pre-heating, pre/post-welding cleaning, etc.).

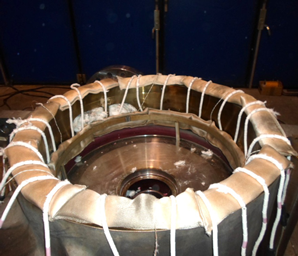

Alphasar decided to invest heavily in the purchase of a robotic welding station for welding on parts of any material to minimise the possibility of error. The robotic station has the ability to perform coatings on parts of various sizes, weights and geometries:

- Diameter max 1800 mm

- Depth of mechanical arm max. 1000 mm

- Max. weight 7.5 t

Alphasar also has a localised heat treatment (PWHT) unit, which can guarantee our customers the possibility of performing localised stress relief on executed welds. This equipment is subject to continuous monitoring, maintenance, calibration and testing to ensure that the required temperatures are accurate.